L’AVENUE

Shanghai

Illuminated fins

designed, manufactured & integrated into an extraordinary facade.

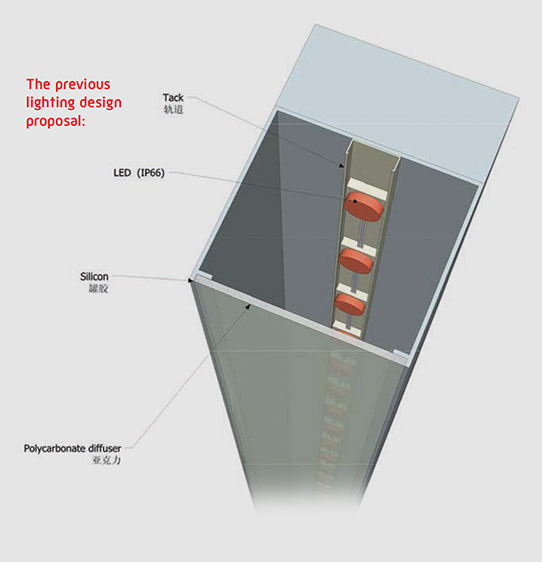

The initial concept for the illumination of the fins.

Redesign

First, there was an existing lighting design but it was impractical. The tender documents contained a concept for the lighting of the fins that used a flexible string of LED nodes. This concept was fatally flawed. We knew from experience that an even illumination of the diffused layer would be impossible with the dimensions we had to work with.

Illumination Physics also makes a number of flexible string type LED products and by uprating the LEDs we could increase the lumen output, but the problem of uneven light distribution would remain. More than this, at illumination Physics we consider the entire genre of flexible plastic LED String type products to be unsuitable external architectural applications. The variation in temperature that occurs in a façade is simply too great for long term survivability. Shanghai’s climate is particularly severe. Another problem with all products of this type is the need to have the extra low voltage power supply unit close to the start of the string.

Tenants of A-grade buildings do not like being disturbed by maintenance operations. But these issues pale into insignificance compared to the problems associated with the physics of constructing a fin with a polycarbonate front panel. First, there is the structural integrity.

THE CHALLENGE

Physics and prior art

Continuous linear LED light: illumination Physics has developed several versions of our linear diffused ‘IP Bar’ and numerous reference projects in Hong Kong attest to its effectiveness in either RGB or various white LED versions.

The illumination IP Bar provides is even, bright and the junction between one luminaire and the next invisible when illuminated. IP Bar was also extremely robust, able to withstand heavy impacts (carless use of the gondola during façade maintenance or window cleaning can be a culprit).

IP Bar is also fitted with Gore-Tex vents, allowing the air pressure within the luminaire to remain equalised with the outside environment. Gore- Tex will allow air to escape when the luminaire is heated as the gas inside tries to expand (according to Charles’s Law) and air to re-enter the luminaire when it is cooled and the gas contracts. Only gas can pass the vent, not moisture. The Gore-Tex vented IP Bar is always in a pressure equilibrium, containing neither a relative positive pressure or vacuum thus its seals are never stressed.

There was another feature of IP Bar making it very suitable as a basis for development into a version suitable for Lux China, namely, the use of an aluminium chassis that held the polycarbonate extrusion.

Composite construction: Polycarbonate is ideal for the containment of the LEDs and the electronics. Additionally, it was ideal as a diffused lens material. It could also be compact and still provide a completely even light distribution because in a linear luminaire, the LEDs can be close together. Polycarbonate however is unsuitable as a material for fixings or bracketry which is why almost all linear LED products are of a composite construction, part polycarbonate and part aluminium.

temperature: It is common practice for luminaire manufacturers to bond the metal and plastic parts together using adhesives but illumination Physics has a better way. A building façade and all of its integrated lighting are subject to significant diurnal temperature changes, which can be rapid.

Consider, for example, the façade of a west facing tower baking on a summer’s day in Hong Kong. The façade will reach 60 degrees Celsius (a factor of air temperature plus solar gain) and if the LED system is embedded in that façade, it too will acquire the same or a similar temperature.

In this example, a thunderstorm or a cyclonic weather event then occurs. Wind and a drop in air temperature are accompanied by heavy rain.

THE SOLUTIONS

A rapid cooling of the façade and the luminaires. A change of more than 30 degrees is common in less than half an hour during which the Gore-Tex vents will be equalising the rapid change in internal air pressure to prevent a partial vacuum from forming inside the luminaire. The temperature change matters for another important reason because the coefficient of linear expansion for aluminium is not the same as polycarbonate. During heating (expansion) and cooling (contraction), the length of either material will vary from the length at which they were manufactured at a certain temperature. If the aluminium is bonded to the polycarbonate, the silicon adhesive joint is constantly stressed by the differential between expansion rates of the two materials. Illumination Physics has solved this problem by NOT bonding the aluminium chassis to the polycarbonate extrusion. Instead, the polycarbonate and aluminium extrusions are designed to slide one inside the other using male and female mounting rails to provide a very strong retention – but without glue bonding. As a consequence, the chassis provides a hard mounting surface whilst still allowing for differential expansion and contraction of the two materials independently without any stress to either.

So far so good. Our existing design philosophy with the IP Bar family of products has provided a proven technology platform for Lux China. Now we need to adapt it to suit some distinctly new challenges. A VMU for the client (visual mock-up) was conducted at our facilities near Hong Kong and three products were demonstrated:

• The flexible string type LED as specified in the original lighting concept

• A 135mm wide handmade linear LED sample

• IP Bar

The IP bar was chosen as the development path to follow.

We were positioned someplace between artisans and mechanics in the battle for this project.

It was Shanghai’s most unusual façade and one in which the lighting systems would be integrated into the structure as if they were an organic part of it and not merely an afterthought, as is often the case in façade lighting.

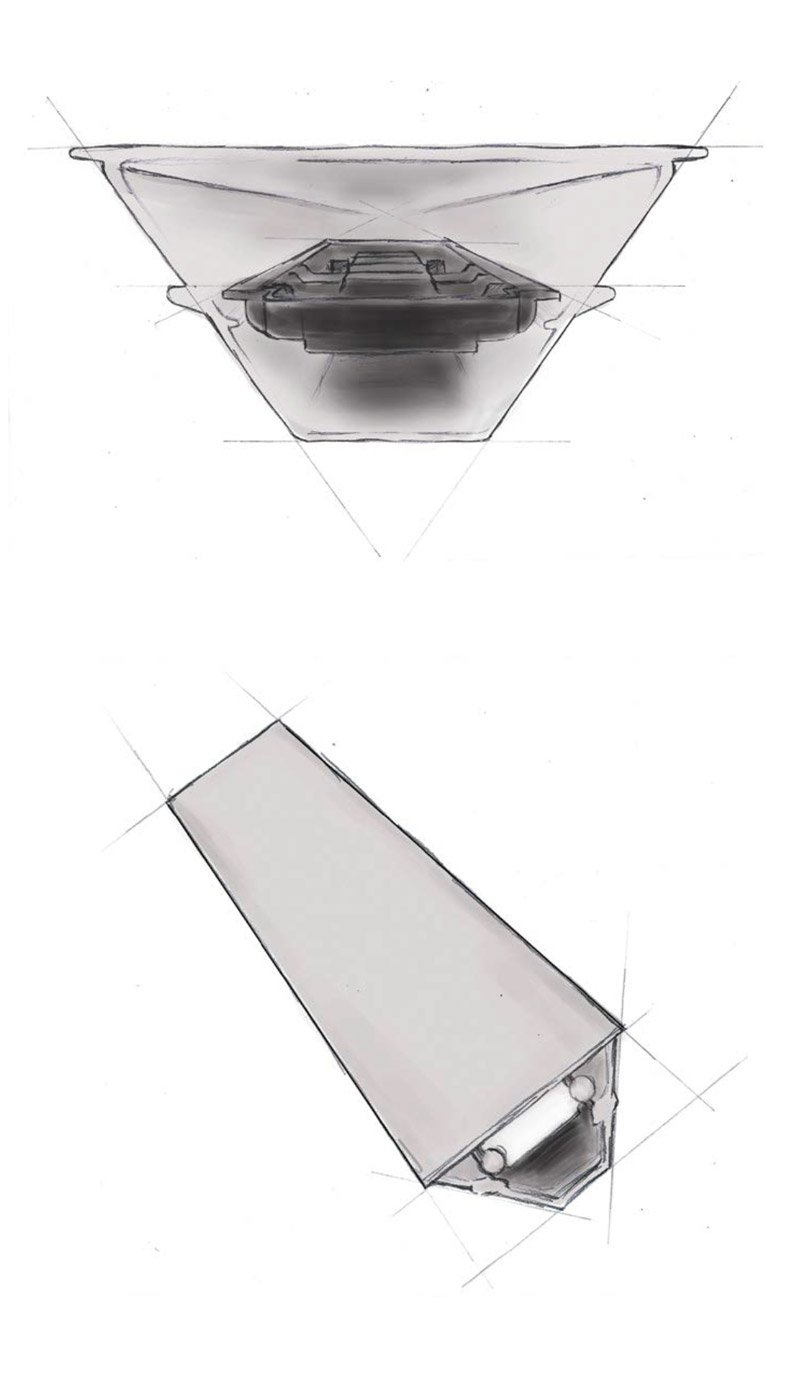

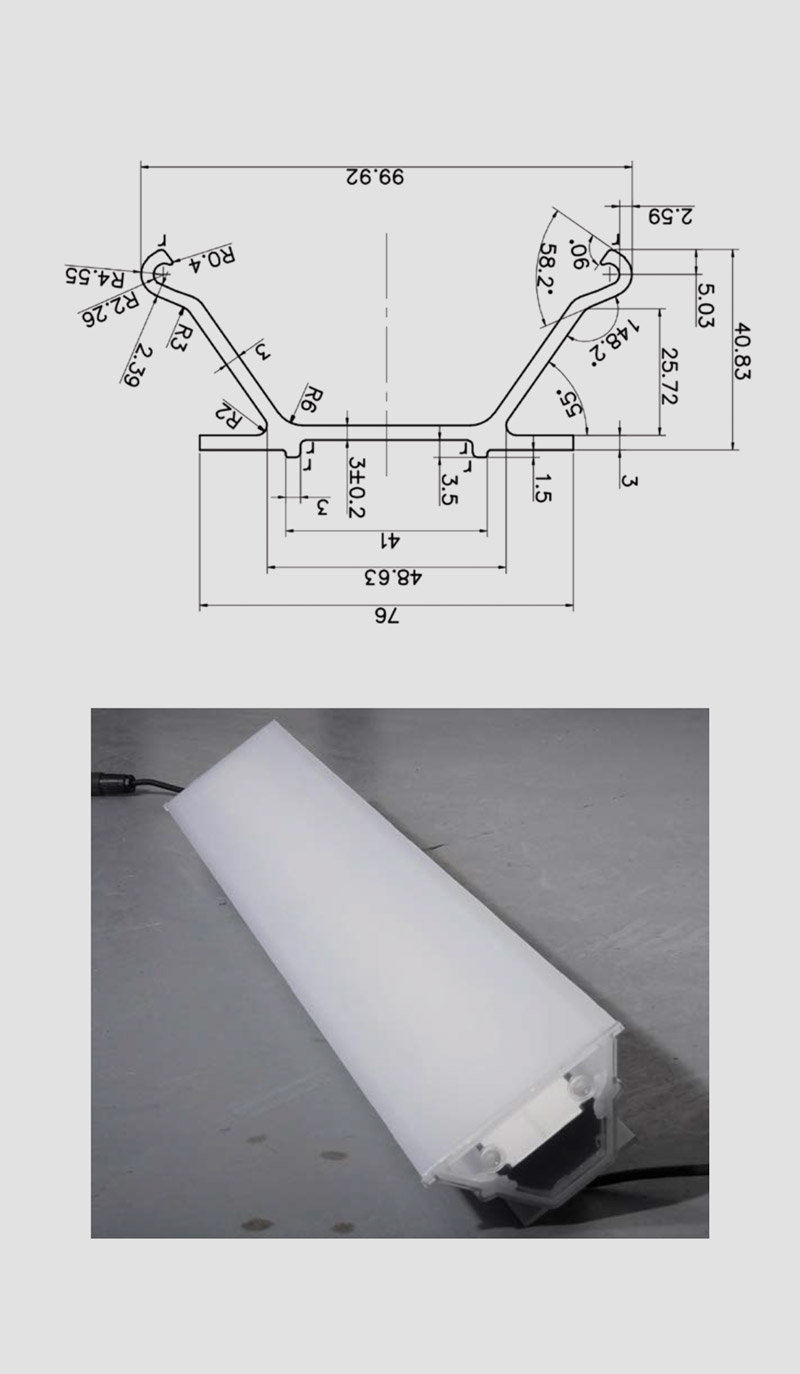

The truncated triangle extrusion seen as the first test extrusion. Such a large polycarbonate shape was and remains extraordinary. The location grooves for the PCB holders are obvious.

As with all previous generations of IP Bar, the PCBs holding the LEDs and other electronics would be contained in a moulded PCB holder that can be flooded with epoxy so that all the components can have secondary protection against ingress.

The devil is in the dimensions

The fins for Lux China are 140mm wide and the illumination is required to fill the full width. Nobody makes a direct view diffused LED tube 140mm wide. There are several reasons for this:

First, there is the optical issue. Bright objects look larger than they really are at night and the visible difference in appearance of a direct view LED strip 50mm wide will not be very different from a 100mm strip (if that existed). So there is no imperative to make such a big fixture under normal circumstances.

Second, the bigger the fixture the more gas it contains. Controlling the air pressure inside becomes more and more troublesome as it is heated or cooled. The ability to vent excess or negative pressure in time may exceed the performance of the Gore-Tex vents.

Third, the bigger the fixture is, the less stable or rigid it becomes, causing durability problems. The seals become insecure and the risk of ingress failure multiplies.

Jun Aoki was taking us in a direction that no off-the-shelf product would ever normally go. We already had the basis of a workable product in IP Bar. Now we needed to more than double its width without destroying its structural integrity.

This could be done in two ways:

• Devising a special cross-sectional shape to create torsional and longitudinal rigidity.

• Keeping the volume as low as possible. Diagonal bracing has been used for a millennia to provide stiffness in architecture. It was possible to create a new ‘IP Bar – Lux’ that had a very wide front surface which would span the full width of the throat of the fin, but the extrusion could be in section, a truncated triangular polygon at the back surface.

The base of the polygon need only be wide enough to mount the electronics and the LED array at the correct distance from the display surface of the diffuser. The diagonal sides would act like braces to stiffen the structure. The aluminium chassis would be used in exactly the same way as all of the other IP Bar products, to stiffen the structure further still and provide the mounting points for the complete luminaire. The new shape both maximised the stiffness and minimised the volume. Now that the volume was known, the properties of the Gore-Tex vents could be calculated based on the maximum rate of temperature change that might occur in Shanghai.

Power and Data Distribution

illumination Physics IP Bar Pro was the donor technology for IP Bar Lux. The original IP Bar luminaires have usually been AC powered (mains voltage) and each luminaire, regardless of length, has an AC to DC transformer inside. The connections between each luminaire are by a composite power and data cable carrying mains voltage and the digital signal that controls the colour and intensity functions of each luminaire. This interconnection method is advantageous as the wiring is simplified and the number of luminaires connected in series is large, helping to reduce penetrations in the building envelope.

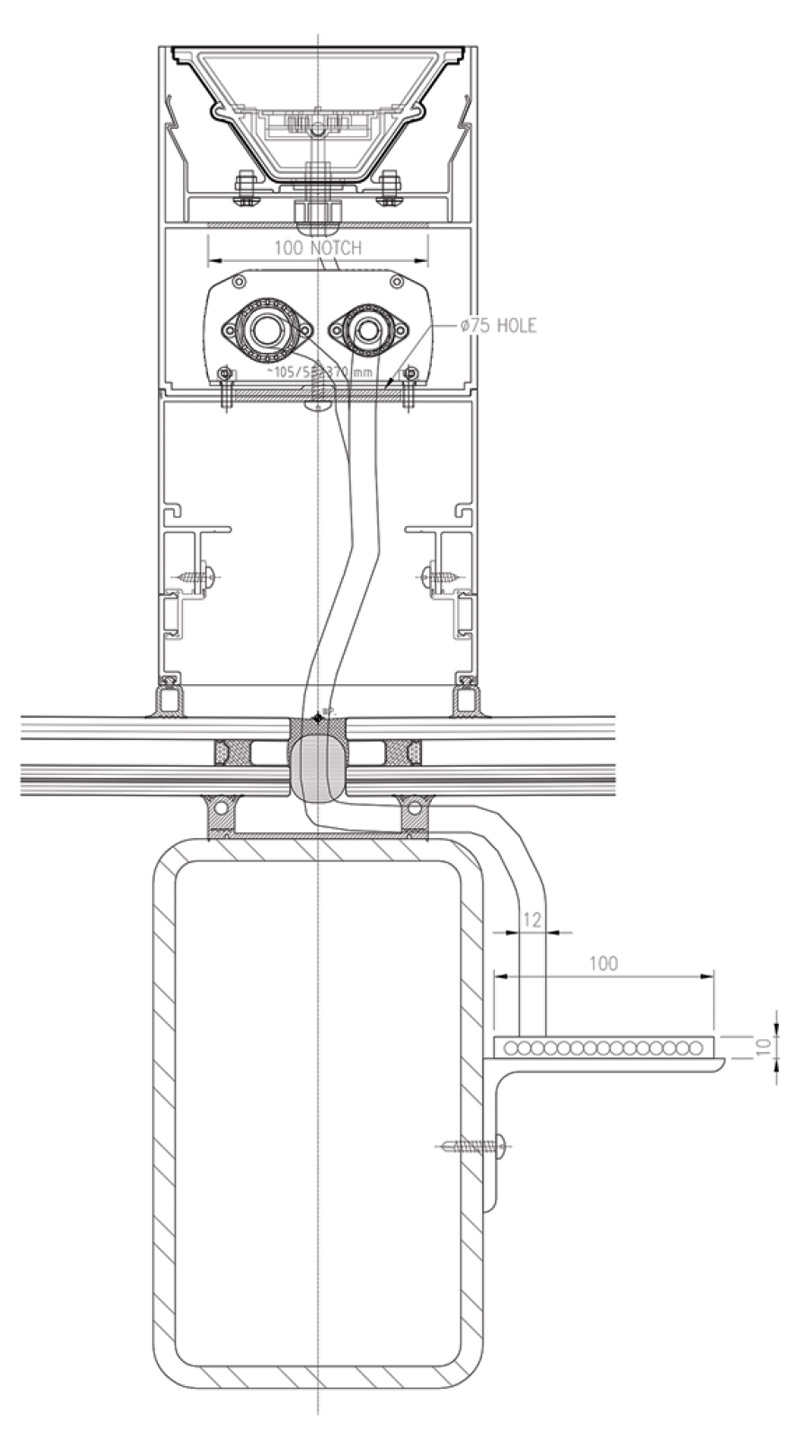

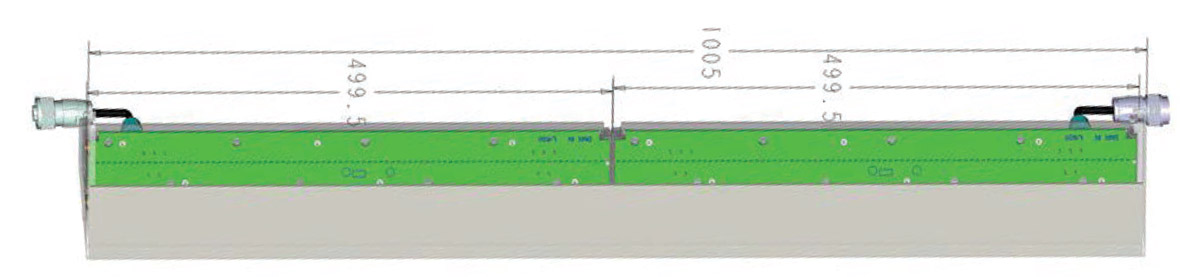

However, because of the truncated triangular section of the special IP Bar Lux, there was no space inside the extrusion for a transformer. However, there was room inside the fins for a larger power supply unit that could perform the same role for all of the luminaires in any one fin. Given that we expected six pieces of 1000mm luminaires and one shorter 500mm luminaire to populate one fin, we could drive all of them with one special PSU.

Furthermore, it could be located below the luminaires in such a way that it could be accessed for maintenance by simply removing one of the IP Bar Lux units.

The PSUs would be connected in series so the number of penetrations per floor could be reduced from twenty four (the original concept design) to just two with the developed illumination Physics design, and no power or data equipment would be placed in tenanted areas.

The power supply and data distribution unit created for each individual fin.

Invisible Fixings

Jun Aoki left no room for negotiation or compromise on this topic. The fins could be seen from the inside of the building and therefore, it would be intolerable for anyscrew or other fixing to be visible. illumination Physics had to devise a method of securely installing the new IP Bar Lux luminaires into the fin in such a way that it met the structural performance standards for security. However, the luminaires must also be removable and replaceable for maintenance.

When designing custom luminaires for integrated façades it is important to be familiar with all of the techniques that façade companies use when designing and assembling the façade itself. illumination Physics has invested heavily in such an education over fifteen years. We have an intimate understanding of how a façade is designed, fabricated and assembled. We are not façade engineers but we are very familiar with the way they work. We knew the use of ‘spring or snap’ fittings which used an interference fit was the key to avoiding bolts or screws to secure the luminaires within the fins. ‘Snap’ fittings are used pervasively, now we needed a special application.

We were fortunate that Josef Gartner employed a very special engineer. Janine Dettki. Rarely have we seen a challenge communicated, understood and solved so quickly. Sketches passed back and forth during time zone conferences in Germany, Melbourne and Shanghai. The profile of the aluminium fin extrusion was modified to incorporate a wedge onto which a spring steel clip attached to the chassis of the IP Bar Lux could latch.

Janine and illumination Physics engineers may have approached the problem from different creeds but it was rapidly solved. Handmade prototypes proved the retention power of our spring loaded snap fitting could pass the wind loads. More, we had a solution for Aoki San’s aesthetics that was inexpensive and better yet. By using a special tool, it was possible to un-latch the spring mechanism so a luminaire could be easily removed from a fin if maintenance was ever required.

Top left sectional drawing of the aluminium chassis for the polycarbonate extrusion.

The first completed IP Bar LUX complete with polycarbonate extrusion and the aluminium chassis. Two Gore-Tex vents can be seen in the end cap.

Due to the constraints of ‘pick and place’ machinery, the length of a linear luminaire is comprised of a number of units of machineable length.

The organic design by Jun Aoki set an extraordinary challenge for illumination Physics.

Never in our experience of bespoke luminaire design had we been pushed to such intricacy. And yet the challenge was welcome.

The surprise

A bombshell arrived in the form of an email from Josef Gartner which contained an Excel spreadsheet listing the position and length of all of the fins on the façade. Every single length was different!

Aoki San’s attention to organic detail had appeared in a place we had not expected, but we should have. If the building is a waterfall and water droplets are random in length, then the metaphorical fins should vary too! This was a problem. We would have to devise a system that could cope with infinitely varying lengths in the fins; these differences could be a few millimetres or by up to one hundred millimetres.

The Pick and Place machines use lasers for accuracy and they are expensive. For this reason, it is very rare to find a Pick and Place machine that can make printed circuit board more than 500mm long. The cost of the machine multiplies according to the maximum size of thecomponent it is capable of producing.

All linear LED luminaires are made up of modules of length that are the normal output lengths of the machines that assemble them. Less than 500mm is typical. In America, the luminaire is available in multiples of its shortest module, one imperial foot or 12 inches, so 1’, 2’,3 ‘and 4’ feet. Any longer than 4’ feet and the fixture is difficult to assemble.

illumination Physics uses decimal metrics and a PCB of 250mm is the typical base module from which we can construct 500mm, 750mm, 1000mm and, if necessary 1250mm and 1500mm fixtures.

Typical industry practice alone will not solve the mathematical puzzle set by Aoki San. In order to illuminate his organically varying fins, illumination Physics would have to dig deeper.

We analysed the one thousand different fin lengths looking for a rhythm in the numbers that would allow us to find some acceptable commonality. Clearly, the normal PCB lengths could not do the job and we would need to make a selection of special pieces.

In the end, we found that by creating seven different length luminaires, we could assemble them in different sequences and combinations so that we could always have a total length that would be within thirty millimetres of the length of the fin. A small handmade metal cover plate would complete the front surface of the fin.

1000 pcs

Illuminated fins

140 mm

wide LED tube

THE OUTCOME

L’Avenue is a new high-class shopping mall and a major landmark building in Shanghai. The visual information of the building contrasts traditional architecture.

L’Avenue is everything except ‘straight’. The corners are not corners, but rather, random turns. The transom lines rise and fall organically and the façade of the tower is not rectilinear, as one has been trained to expect either, as it bulges on one side and bows on another. illumination Physics were not the first lighting professionals to attempt the task. A logical and inevitable design concept had already been drawn. The tower and the upper skin of the podium have been decorated with several thousand metal fins that overlap each other’s dimensions; odds and evens like a crossstitch.

L’Avenue grasps your attention in a way that a rare and truly valuable art piece does. You cannot miss it and you cannot easily look away once you have been captivated.