The Double Tree by Hilton

Zagreb, Croatia

OUR BRIEF

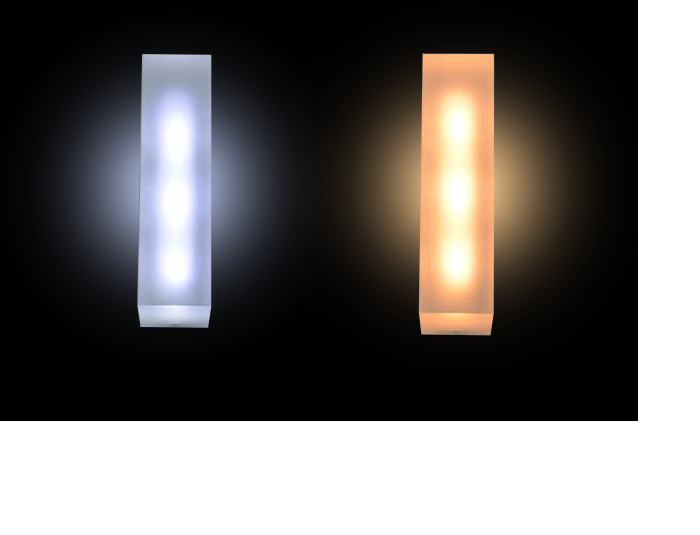

For illumination Physics, familiar golden rules surfaced.

- The lighting must not cause any nuisance for the hotel guests.

- The lighting must not require any electronics or transformers within the guest room areas.

- The maintenance of the lighting system shall be designed so that it does not affect the guests in any way.

- It must appear as if the lighting of this building was pre-determined, not an afterthought, despite the fact we were actually in catch-up mode.

- The polished and metal glass façade design rendered the use of indirect lighting impossible.

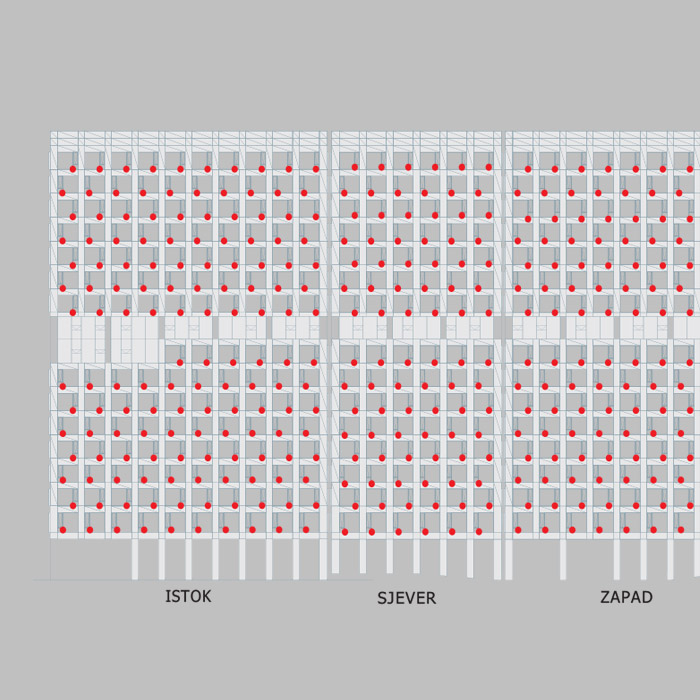

- The façade is of a conventional unitised curtain wall genre; the interconnecting panels will be brought to site and hung from the upper concrete floor slab. Unitised curtain walls are very efficient to build and promote high quality control as they are manufactured in a controlled factory environment. The down side is that they all tend to look similar and the only opportunities to differentiate one from the other are in the texture details. Decorative fins are commonly used to add character and break up the slab-sided nature of a unitised façade. illumination Physics ensured this approach was followed at the Double Tree Hilton, with the exception of one remarkable difference – the decorative fins were to be made of wood!

OUR SOLUTION

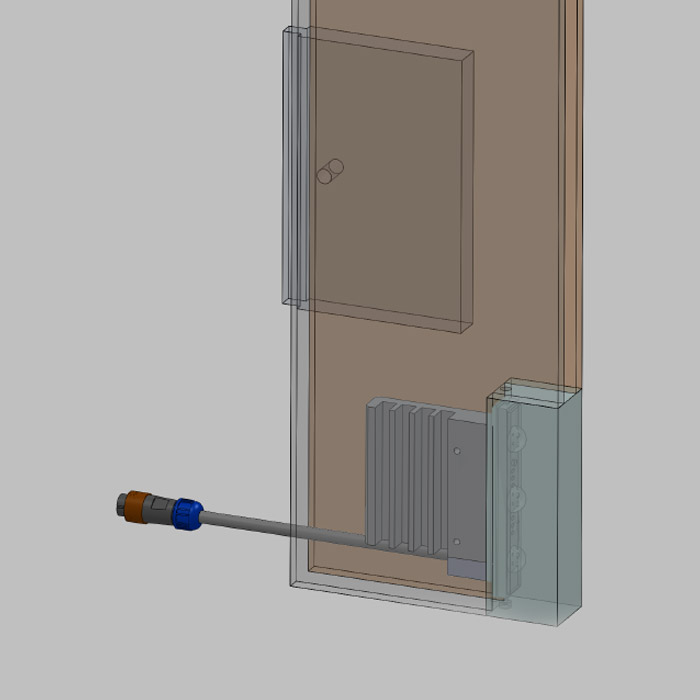

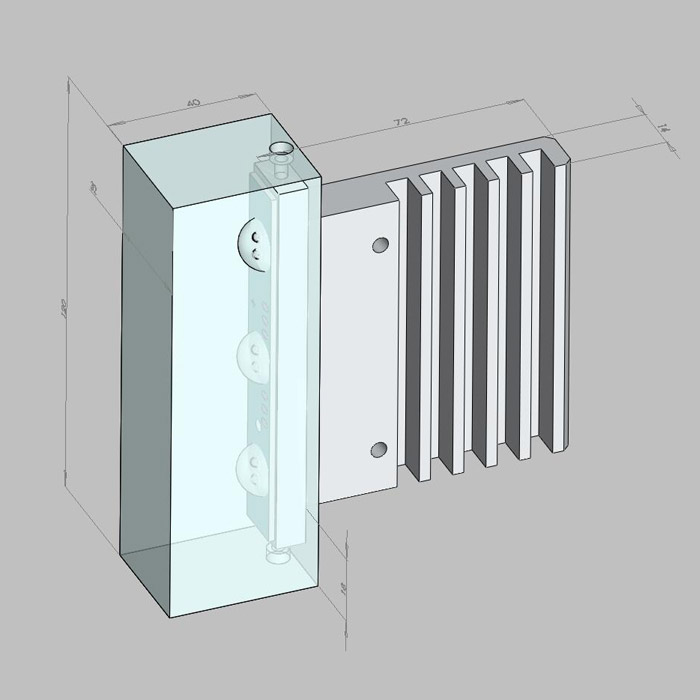

Air was drawn in at the base of the fin, passing over the heatsink of the luminaire and exhausted at the back of the fins via an invisible ventilation slot.

Accommodation of the new luminaire into the façade system required a specially made cable connector with a very narrow diameter of only 16mm so that it could easily pass through the aluminium mullions of the façade system.

The electronic design of the luminaire system was driven by a simple choice; do we include electronics ‘on-board’ each light fixture or do we simplify the luminaire to the extent that it contains only LEDs and nothing else?

For illumination Physics, the decision was obvious. We have no imperative driving us to sell off-the-shelf products; we design products for each project specifically. LED fixtures with DMX on-board may be tempting to use in some environments but the Double Tree Hilton was not one of those. On the contrary, everything was wrong with such a notion!

The luminaire had to be so compact that the packaging of any electronics was very problematic.

Whilst the operational temperature in the luminaire was manageable for the LEDs, this was not the case for the electronics, which have a heat tolerance less than half of the LEDs.

From a life expectancy and maintainability perspective, electronics ‘on-board’ made no sense. With internal LEDs inside only, the life expectancy of the new IP luminaire would be 70,000 hours. With electronics on-board, the life expectancy of the total fixture would be reduced to that of the shortest living electronic component, perhaps 10,000 to 15,000 hours.

There was also no benefit in an ‘in-series’ electronic design for this building, because of the fin lay-out it would be actually harder to install.

The most logical lighting system design was to use remote drivers located in the easily accessible building core. The luminaires would be reduced to the ultimate durability born of simplicity, connected to those drivers by cables carrying no data, just low voltage.

Indestructible.

As always, illumination Physics tailored a complete solution including the design and configuration of the control system. A complete package of control schematics and data distribution products was supplied with the drivers and luminaires. Our intimate understanding of the construction process for modern façades enabled us to deliver an integrated and innovative lighting system that could be installed without extending the overall construction phase.

Another example of

illumination Physics’

in-built design.

PRODUCTS

- 468 x Custom light fixtures

- 78 x HP led driver 48VDC

- 4 x DMX splitters

- 1 x X-net 8 ethernet/DMX converter